Description

Comprehensive Guide to PPE Kit Packing Material

Personal Protective Equipment (PPE) kits have become indispensable in ensuring the safety of individuals in various sectors, especially healthcare, industrial, and emergency services. Proper packing material of kits is crucial to maintain the integrity and effectiveness of the protective gear. This article explores the essential aspects of PPE packing material, emphasizing its importance, key features, and environmental considerations.

Importance of PPE Kit Packing Material

- Protection: The primary function of kit packing material is to protect the contents from contamination, damage, and degradation. This ensures that the PPE remains effective when used.

- Sterility: For medical PPE , maintaining sterility is crucial. Packing material must prevent the ingress of pathogens and contaminants.

- Durability: Packing material must withstand handling, transportation, and storage conditions without compromising the integrity of the PPE.

- Compliance: Packing material must comply with regulatory standards and guidelines to ensure safety and efficacy.

Key Features of Effective PPE Kit Packing Material

- Material Composition: Common materials used include polyethylene (PE), polypropylene (PP), and laminated films. These materials offer a balance of strength, flexibility, and barrier properties for effective packing material.

- Sealing Mechanisms: Heat sealing and adhesive sealing are commonly used to ensure airtight and watertight closures in packing material, preventing contamination.

- Transparency: Clear packing material allows for easy identification of contents without opening the package, reducing the risk of contamination.

- Labeling: Proper labeling with information such as expiration date, batch number, and usage instructions is essential for safety and compliance of the packing material.

- Tear Resistance: High tear resistance prevents accidental breaches during handling and transportation, ensuring the packing material remains intact.

Types of PPE Kit Packing Material

- Plastic Bags: Often made from PE or PP, these bags are lightweight, durable, and provide excellent barrier properties as packing material.

- Laminated Films: These films combine multiple layers of materials to enhance strength, barrier properties, and durability. They are ideal for vacuum-sealed kits as packing material.

- Foil Pouches: Used for high-level protection, especially in sterile environments, foil pouches provide an excellent barrier against moisture, light, and contaminants as packing material.

- Cardboard Boxes: Used for secondary packaging, cardboard boxes offer structural support and protection during transportation and storage as packing material.

Environmental Considerations

- Recyclability: Choosing recyclable packing material helps reduce the environmental impact of kit packaging. PE and PP are widely recyclable.

- Biodegradable Options: Emerging biodegradable packing material offers an eco-friendly alternative, reducing long-term environmental impact.

- Minimalistic Packaging: Reducing the amount of packing material used in packaging without compromising protection can decrease waste and resource consumption.

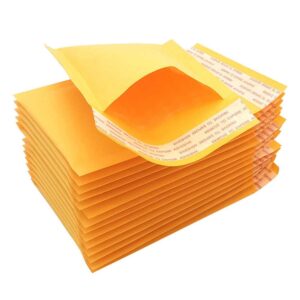

PPE kit packing materials often utilize specialized courier bags designed to ensure the safe and secure transport of essential protective equipment :

- Size and Capacity: Courier bags come in various sizes and capacities to accommodate different types and quantities of kits. They range from small bags for individual kits to larger bags for bulk shipments.

- Protection from Contaminants: Courier bags provide a barrier against moisture, dust, and contaminants during transportation. This helps maintain the sterility and cleanliness of the PPE components inside the bag until they reach their destination.

- Tamper-Evident Features: Many courier bags used for kits include tamper-evident seals or closures. These features ensure that the bag has not been opened or tampered with during transit, enhancing the security and integrity of the contents.

- Durability: Made from durable materials such as polyethylene (PE) or polypropylene (PP), courier bags are strong and tear-resistant. This ensures that the kits are protected from damage during handling and transportation.

- Customizable Branding: Courier bags can be customized with branding, logos, and labels that provide essential information about the contents, such as batch numbers, expiration dates, and handling instructions. This facilitates easy identification and compliance with regulatory requirements.

- Easy Handling: Designed for ease of handling, courier bags often feature ergonomic handles or grips for comfortable carrying. This is especially beneficial for courier and delivery personnel who need to transport kits efficiently and safely.

- Environmentally Friendly Options: Increasingly, there are environmentally friendly courier bag options available, such as biodegradable or recyclable materials. These options help reduce the environmental impact of packaging waste associated with kits.

- Security Features: Some courier bags may include additional security features such as barcode labels, tracking numbers, or RFID (Radio Frequency Identification) tags. These features help monitor the location and status of the kits during transit, ensuring they arrive safely and on time.

- Compliance and Safety: Courier bags used for kits comply with industry standards and regulations for packaging and transportation of medical and protective equipment. They ensure that kits are delivered safely and securely to healthcare facilities, frontline workers, or end-users.

Reviews

There are no reviews yet.